30January

Exothermic welding, also known as thermite welding, is a crucial process in various industries, particularly in electrical grounding and bonding.

Exothermic welding, also known as thermite welding, is a crucial process in various industries, particularly in electrical grounding and bonding. Here’s a comprehensive overview of exothermically welded connections, their applications, and their benefits.

What is Exothermic Welding?

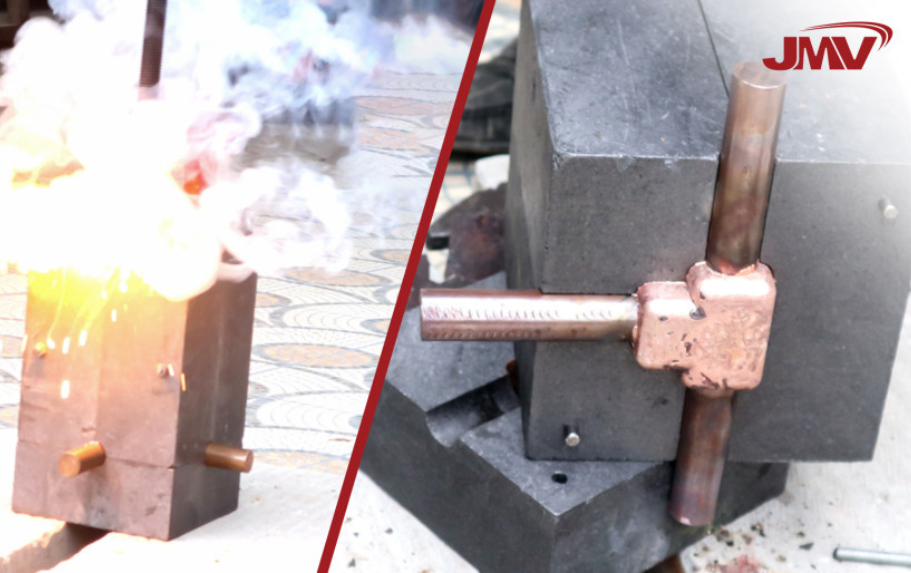

Exothermic welding is a technique used to join conductors by creating a strong, lasting bond. This method is particularly advantageous because, once initiated, it operates without the need for external heat sources or electricity. Its efficiency and portability make it an ideal solution for various applications in electrical connections and grounding systems. The process ensures reliable and durable joints, which are essential for maintaining the integrity of electrical installations.

The Exothermic Welding Process

Preparation:

- Clean Surfaces: The conductors to be welded must be thoroughly cleaned to remove any contaminants such as dirt, oil, or oxidation. Proper cleaning ensures a strong and effective weld.

- Mold Setup: A graphite mold is used to shape the weld. The mold is designed to fit the specific size and type of conductors being joined. It is crucial to ensure the mold is dry and free from any moisture.

Positioning Conductors:

- The cleaned conductors are placed in the mold, ensuring they are properly aligned and securely positioned. This alignment is essential for creating a strong weld.

Welding Material:

- Weld Powder: Exothermic welding utilizes a specialized weld powder. This powder is packed into a metal crucible that is part of the mold assembly.

- Ignition Powder: A small amount of ignition powder is placed on top of the weld powder. This powder is ignited to initiate the welding process.

Ignition:

- The ignition powder is ignited using a flint gun or an electric igniter. Once ignited, the reaction proceeds rapidly, generating intense heat and molten metal.

Exothermic Reaction:

The welding powder produces molten metal and slag. The molten metal flows into the mold cavity, surrounding the conductors and forming a solid, homogenous weld.

Cooling:

- The mold is allowed to cool for a few seconds to a few minutes, depending on the size of the weld. Once cooled, the mold is removed, revealing the finished weld.

Finishing:

- Any excess slag or residue is cleaned off, and the weld is inspected to ensure it meets the required standards.

Applications of Exothermic Welding

Exothermic welding is widely used in various sectors due to its durability and efficiency. Key applications include:

- Electrical Grounding and Bonding: Ensuring a reliable grounding system in power plants, substations, and telecommunications towers.

- Railway and Transportation: Connecting rail tracks and signaling systems.

- Cathodic Protection: Protecting pipelines, storage tanks, and other metal structures from corrosion.

- Lightning Protection: Essential in lightning protection systems to ensure reliable and effective grounding.

Benefits of Exothermic Welding

Strong and Durable: Exothermic welds are molecular bonds, making them extremely strong and durable.

Corrosion-Resistant: The welds are resistant to corrosion, ensuring a long-lasting connection.

No External Power Required: The process does not require an external power source, making it suitable for remote locations.

Low Maintenance: Exothermic welds are maintenance-free, reducing long-term costs and effort.

Conclusion

Exothermic welding is an essential technique in modern electrical and construction industries, offering unmatched reliability and performance. Its ability to create strong, conductive, and durable connections makes it a preferred choice for critical applications. As technology advances, exothermic welding continues to evolve, providing even greater efficiency and versatility in ensuring the safety and effectiveness of electrical systems.

Understanding the basics of exothermic welding can help industry professionals make informed decisions about their grounding and bonding solutions, ultimately enhancing the safety and reliability of their projects.

.png)

.png)

.png)

.png)